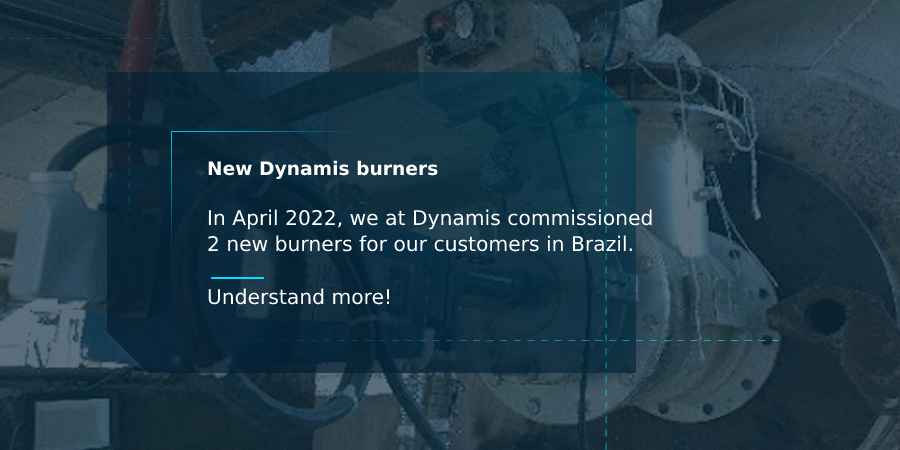

In April 2022, we at Dynamis commissioned 2 new burners for our customers in Brazil. Understand more!

In the last month of April 2022, DYNAMIS commissioned 2 new burners for its customers in Brazil, these are 2 projects dedicated to their applications, being 100% developed for the required demands of each project and specified by the respective clients.

These 02 success cases of DYNAMIS combustion technologies supplied to the main cement producers in Brazil are shared below with all DYNAMIS clients to help them in the most diverse applications that may require any type of burner.

D-FLEX & D-FLAME: INTERCEMENT BODOQUENA CASE

DYNAMIS commissioned a new D-FLEX burner for INTERCEMENT BODOQUENA, as an auxiliary burner, for heating the gases going to the calciner through the tertiary air duct. The burner runs with fuel oil in a capacity of 12 Gcal/h, and its design characteristics are listed below:

- Thermal Power: 12 Gcal/h / 14 MW

- Fuel: Heavy Oil

- Construction: Type: Multichannel / Heavy-Duty / High Flame Shape Adjustment Flexibility

- New oil rack

- D-Igniter as pilot burner for ignition

- BMS – Burner Management System with flame programmer

- Accessories: Flame sensor, valves, pressure indicators and flexible hoses

Figures of the DYNAMIS D-FLEX burner project and its application in the IC plant

As mentioned before, this DYNAMIS D-FLEX burner is used by the plant to heat the calciner, which is mounted in a separate line from the kiln gases, being activated after the maintenance outage, before the start of petcoke injection in the kiln main burner.

Figures of the DYNAMIS D-FLEX burner operation in tertiary air heating operation

At the same time with the D-FLEX burner for heating the tertiary air, IC started up and put into operation the DYNAMIS pilot burner, the D-IGNITER, for application in the main burner of the clinker rotary kiln, also a DYNAMIS D-FLAME burner, supplied in 2021.

The two D-IGNITERs (in the auxiliary burner and in the kiln burner) are powered by the same LPG rack and controlled by the same BMS.

As mentioned before, DYNAMIS also supplied a new D-FLAME burner to the same plant in 2021, in which the client asked for a high flame impulse (flame momentum N/MW), characteristic demanded by all INTERCEMENT plants, with the aim of improving the quality and production of clinker and the use of high sulfur fuels. In this D-FLAME main burner project, there was a highly challenging design and supply deadline of 90 days to support the needs and planning of the Bodoquena plant, a deadline within which DYNAMIS once again met.

Figures of the DYNAMIS D-FLAME burner supplied in 2021 for IC ODOQUENA

D-FLAME: VOTORANTIM CIMENTOS SOBRAL CASE

One more DYNAMIS D-FLAME burner for clinker kiln also came into operation last month, and this time, another burner for VOTORANTIM CIMENTOS, in its kiln 2 of Sobral plant. This D-FLAME burner, which was previously supplied by DYNAMIS, underwent refurbishment and design improvements, operate with 100% petroleum coke with a high sulfur content, and the kiln is heated with diesel

Along with the burner refurbishment, a study was carried out by DYNAMIS, to take advantage of existing blowers in the plant, and the burner adjustment air manifold was modified and splitted, leaving one machine only for external air and another for the air channels. tangential and internal. In this way, the external air blower operates with higher pressures, around 400 mbar, and the tangential air blower can operate with lower pressures, reaching an improvement in production with higher operational stability using high sulfur fuels, with an increase in the flame moment of the burner

With this, the plant will reduce the consumption of electric energy, then operating with 2 blowers, to supply primary air to the burner, the butterfly valves can be 100% open and the pressures are adjusted with the rotation of the machines and not with loss of loading on the valves, which is the traditional way when there is only one manifold for all the burner adjustment air channels.

New Manifold for new operation with 2 adjustment air blowers for DYNAMIS D-FLAME burner

Furthermore, with this configuration, it is possible to remotely modify the flame setting directly from the control room without having to actuate the manifold valves in person, which facilitates the operation of the burner.

But the unique feature of this project was the refurbishment of the DYNAMIS D-FLAME burner for ease of maintenance, due to limitations of load movement on the kiln platform. Thus, DYNAMIS elaborated an improvement of the burner design that aims to facilitate its disassembly, raising it in two parts to reduce load weight, so that only the first flange must be released to remove the burner jacket with refractory concrete, solving the disassembly difficulty from the previous burner, and now it is possible to move the 2 sets separately (body and burner jacket) and mount them on the car in a more practical way, respecting the limitations of the available hoist.

Illustrative drawing of the D-FLAME burner modification project so that its body can be removed separately from the burner jacket

Installation and operation of the refurbished DYNAMIS D-FLAME burner for VC SOBRAL in the kiln 2

Contact DYNAMIS, as VOTORANTIM CIMENTOS and INTERCEMENT, and develop your exclusive burner project with DYNAMIS, leader in burners in Brazil and South America, as DYNAMIS is always available to help all clients in Brazil and around the world, quickly and expertly, with the best combustion and process engineers.

Want to improve the quality of your clinker?

Want to gain productivity in the rotary kiln and cement grinding?

Do you want to automate the operation of your burner?

Contact DYNAMIS and make an appointment for a D-FLAME to your kiln.

Dynamis Team