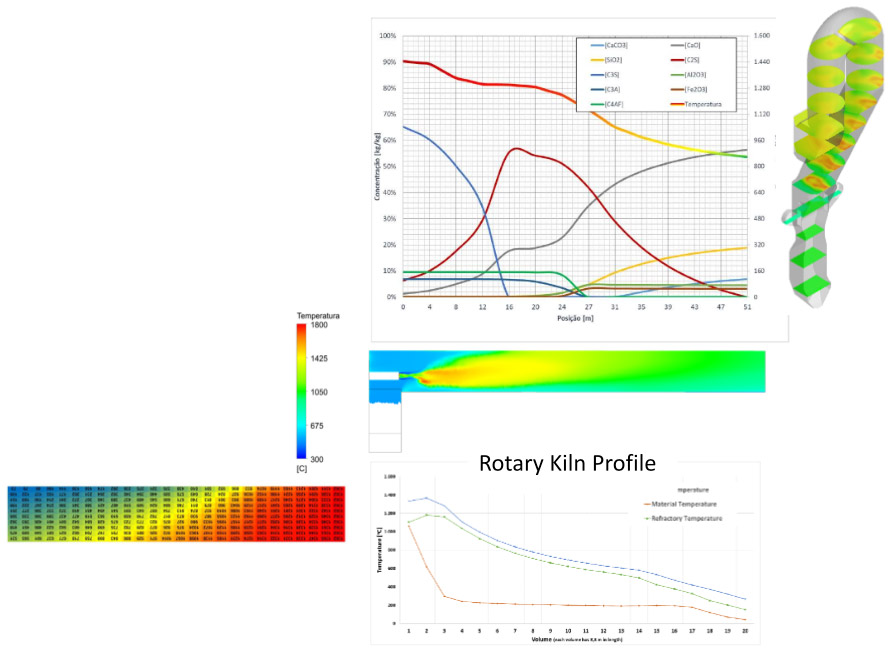

Kiln and Cooler Study

Dynamis’ study of kilns and coolers analyzes temperature profiles of the kiln shell, refractory liners, material bed, heat transfer, analysis of the type of reaction being drying, calcining, sintering, etc, indicating the complete chemical reactions and the formation/decomposition of each material in the product bed, exposing exactly what happens inside the rotary kiln and along its entire length, that is, opening a black box and clearly demonstrating for a better understanding of your process.

Studies can be carried out to evaluate:

In this study, Dynamis:

Global Mass and Energy Balance

Preheater CFD

Kiln Burner CFD

Kiln simulation with D-RK software

Cooler simulation with D-GCooler software

With the kiln and cooler studies of Dynamis, it is possible to carry out in-depth and detailed analysis of the process to optimize and propose alternatives focused on the objective of the study, whether an improvement or increase in capacity, meeting the customer’s needs and respecting the system’s operating limitations.