One of the major industry problems is Nitrogen Oxides (NOx) emissions, controlled by environmental agencies. These gases form due to the high temperatures of thermal processes, and many companies cannot control their emissions. Therefore, they are forced to inject gases to reduce NOx, significantly affecting their operational costs.

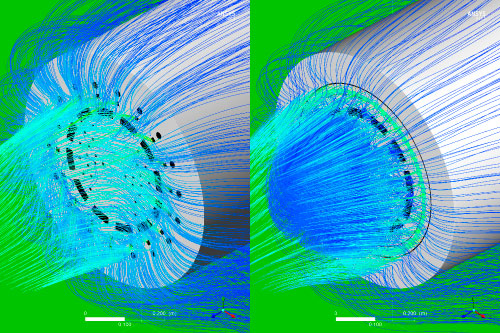

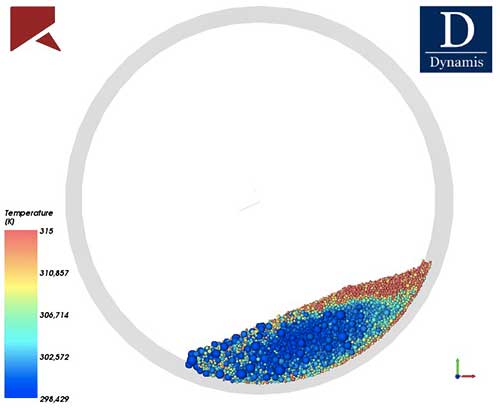

Dynamis offers a customized and complete solution for the reduction of NOx emissions. Consequently, it has an impact on cost reduction resulted from NOx reduction. This solution starts with a data collection at the customer’s plant and a simulation of the current operational condition. After the simulation, an engineering study involving methods and tools for kiln evaluation is carried out. In this study, computational fluid dynamics simulations are used in the application of complex models to simulate chemical kinetics and turbulence in industrial combustion processes. Thus, it is possible to define which equipment and processes will have the most effect in reducing nitrogen oxides emissions. By the end of the study, Dynamis is able to predict with reasonable precision the possible NOx reduction after implementing the modifications recommended.

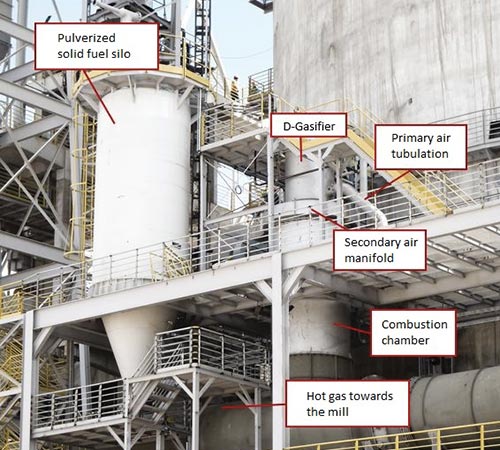

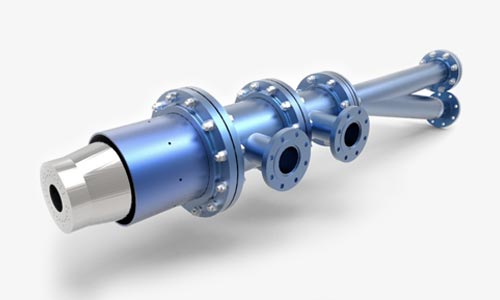

Pelletizing furnaces are an example of NOx emitters in the mining industry. The operational conditions of these furnaces, such as high temperatures and high air index, are conducive to the formation of these gases. In such cases, Dynamis may propose some modifications to the system, depending on the results of the preliminary studies. The optimization of the burner tip geometry, the installation of a D-Gasifier or fuel substitution are possible measures for the reduction of NOx emission in pelletizing.