Dynamis software for mass and energy balance can be applied in different industries. Know more!

DYNAMIS works with tools developed internally for various purposes. One of these tools is used to calculate the mass and energy balance of different processes. This type of calculation allows a quick analysis of the current situation of your process and helps to identify bottlenecks. It is also used in the design of new systems, being useful for the dimensioning of equipment.

One of these tools is our home-made software for calculus of the mass and energy balance to different processes. This type of calculation allows you to quickly analyze the current situation and status of your process and helps to identify bottlenecks. It is also used in the design of new systems and plants, being useful for equipment dimensioning and defining the best process route.

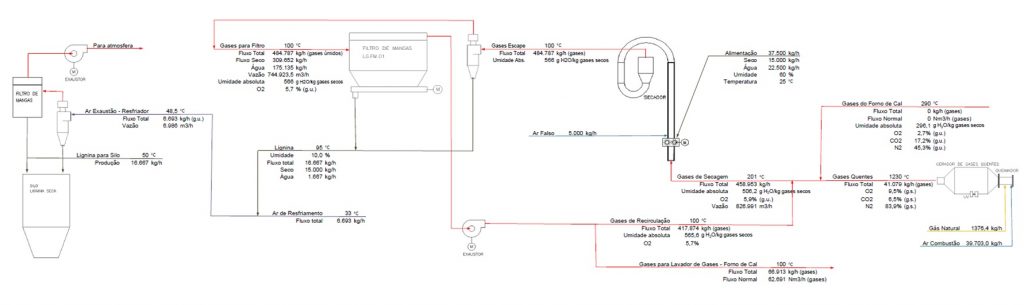

Case 01: Application in Pulp and Paper Industry

For example, Dynamis was responsible for the design of a lignin drying line for an important customer of Pulp and Paper industry, also supplying the equipment for this line, such as a flash dryer, hot gas generator in the line, condenser type heat exchanger, etc.

The development of this project was initiated using our mass and energy balance home-made software, so that essential process variables were calculated such as the quantity of hot gases, gas temperature, quantity of recirculated gases, etc., and these variables were used in the design equipment supplied by Dynamis and auxiliary equipment. Including that the new lignin plant was also to be integrated with the existing lime reburning rotary kiln so that the kiln’s gases could be used.

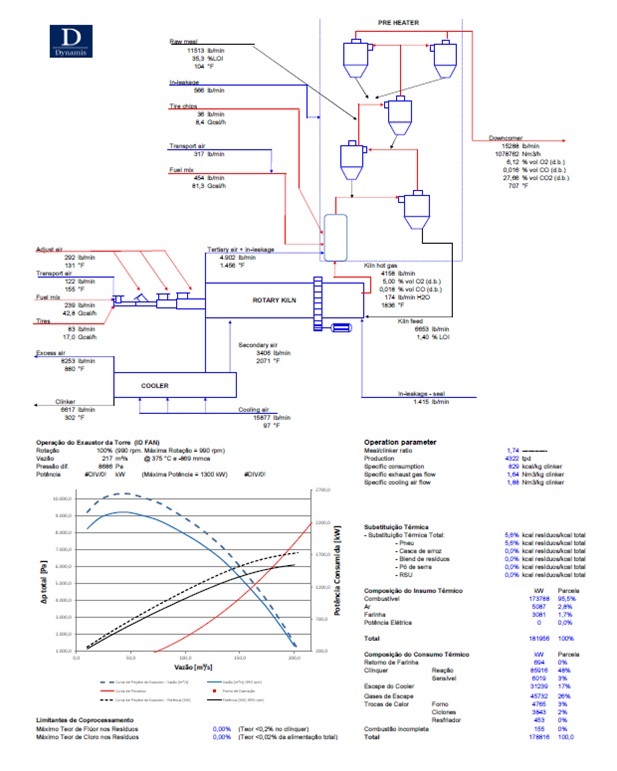

Case 02: Application in Cement Industry

Another application of the Dynamis mass and energy balance calculation software is the generation of input data for CFD (Computational Fluid Dynamics) simulations of cement kiln calciners.

Before executing the simulations in CFD, an analytical evaluation of the existing situation is made through a mass and energy balance of the control volume to be studied.

This balance is used to define the parameters of several variables, “taking a picture” of the process as it is, and is used to calibrate the simulation of the base case in the CFD. Subsequently, new simulations are carried out with objectives such as reducing NOx, in the increase in production capacity, use or increase in the consumption of alternative fuel for co-processing, etc.

Dynamis has expertise in different areas of engineering studies, whether in Cement, Mining, Steel or Pulp and Paper industries, and develops its own tools and software for some applications, with proven results in several projects since 2013. Analyzing existing processes, designing new systems or plants, Dynamis can help your company in countless ways, with the confidence that the best solution will be presented, and using tailor-made tools and software to bring the best solutions to your process.

Team Dynamis