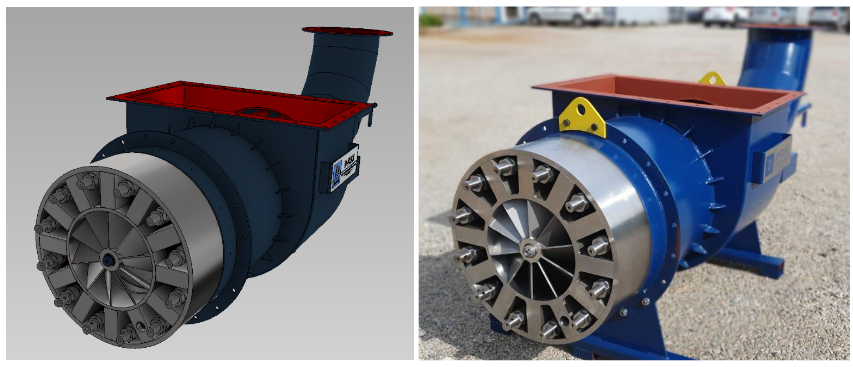

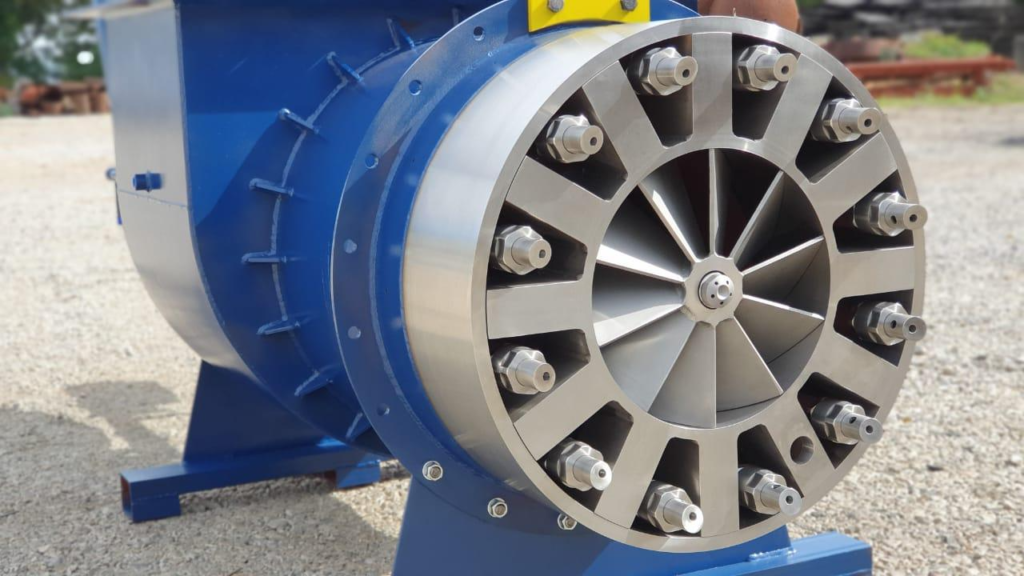

The Dynamis D-Flex burner is a equipment used in several industries and, as it is flexible, it is ideal for burning multiple fuels, also offering great operating flexibility in its combustion air regulation, with a high turndown, minimum fuel consumption and a low level of emission of pollutants.

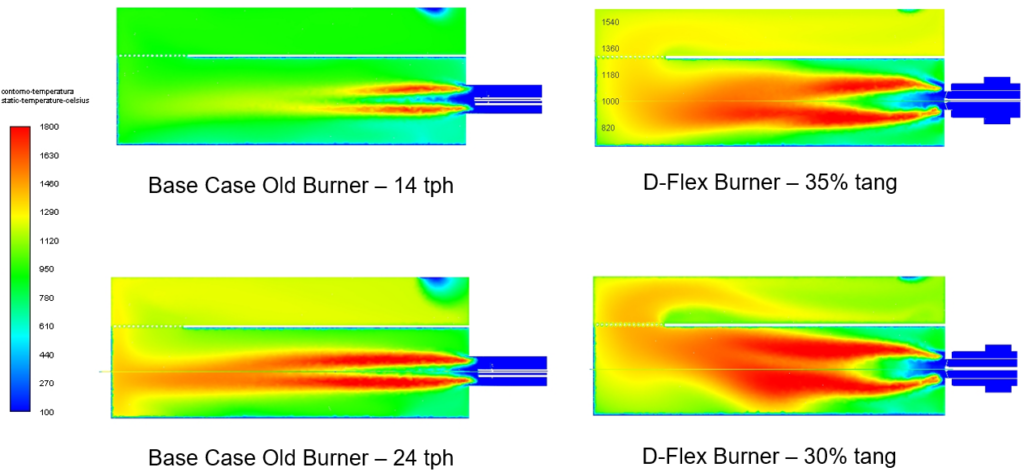

Recently, Dynamis was contracted to improve the performance of a steam boiler, to increase the efficiency of its system. The big problem in this case was that the original burner used had to be operated at low intensity, because it had a long flame shape in normal operation and thus had the possibility of compromising the boiler water piping.

The following table shows the specifications of the new customer-supplied D-Flex burner:

| Parameter | Value |

| Equipment | D-FLEX Burner |

| Nominal Capacity | 20 Gcal/h |

| Main Fuel | Natural Gas |

| PCI of Main Fuel | 48,0 MJ/kg (11.500 kcal/kg) |

| Maximum Consumption of Main Fuel | 1.720 kg/h |

| Minimum Consumption of Main Fuel | 350 kg/h |

| Maximum Supply Pressure | 300 mbar (g) |

| Secondary Fuel | Fuel Oil (Diesel-1/2/4A) |

| PCI of Secondary Fuel | Approx. 40,0 MJ/kg (9.500 kcal/kg) |

| Maximum Consumption of Secondary Fuel | 2.100 kg/h |

| Minimum Consumption of Secondary Fuel | 420 kg/h |

| Excess Air | 5 a 15% |

| Maximum Combustion Air Flow | 33.400 kg/h |

| Estimated Burner Feed Pressure | 530 mm H2O (g) |

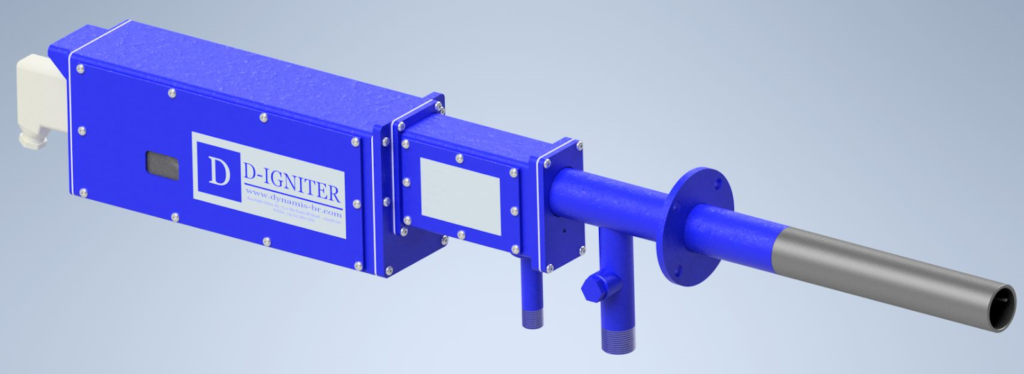

| Ignition | D-IGNITER (Gas Pilot) |

O time de engenharia da Dynamis, analisando as dificuldades de processo e operacionais, também suportado por nosso estudo de CFD do caso, possibilitou que o fornecimento do novo queimador D-Flex a Gás Natural e óleo tivesse uma operação com formato de chama mais curto, mais intensa e mais estável, sem o risco de o perfil da chama chegar com altas temperaturas próximo as paredes dos tubos d’água da caldeira, garantindo não apenas a performance do equipamento, mas a longevidade e a redução na manutenção do sistema.

The Dynamis engineering team, analyzing the process and operational difficulties, also supported by our CFD study of the case, enabled the supply of the new D-Flex burner to Natural Gas and Oil to have an operation with a shorter flame profile, more intense and more stable, without the risk of the flame profile reaching the walls of the boiler’s water tubes with high temperatures, guaranteeing not only the performance of the equipment, but also the longevity and reduction in maintenance of the system.

The scope of supply of the D-Flex burner to the Boiler also included a pilot burner by Dynamis, the D-Igniter, an automatic ignition system, which guarantees a safe and reliable start-up, fail-safe, available and activated whenever necessary.

As a result of our engineering team and the supply of our equipment, the steam boiler was finally able to reach the expected steam production target and once again Dynamis delivered quality and reliable service to our clients, with guaranteed satisfaction.

D-FLEX BURNER UPDATE FOR BOILER APPLICATION

Dynamis, in addition to always seeking to offer the best product and service to its clients, is also available to meet different solutions. An example that proves this Dynamis policy is that for the same D-Flex burner, the customer requested the change of the energy matrix, adding LPG as a new fuel, contacting Dynamis for a new update of its system, with the minimum investment and system intervention.

For the company to be satisfied with its “new” burner, Dynamis supplies in this update a new set of LPG nozzles for the burner and ignitor, which will be interchangeable (by nut) with the current NG nozzles, in addition to adapting the gas valve train adding a new pressure control valves (PCV) and a flow control valves (FCV) and respective manual blocking sphere valves to maneuver the alternating operation between NG and LPG, emphasizing that it was not necessary to acquire new equipment, that is, it was reused almost completely the D-Flex burner, the ignitor and the gas rack, but respecting the operations with both fuels and minimally impacting the project budget, aiming at the best cost benefit for the customer.

At Dynamis, our products are developed with excellence to meet the process, operation and maintenance needs of our customers, taking advantage of the most advanced technologies and our vast experience to achieve the best results.

Whether you need to replace a burner or update your design to meet new specifications, we are ready to provide the technical support you demand.

Contact DYNAMIS and make an inquiry for a D-FLEX for your application.