Learn more about our combustion projects 100% dedicated to customers and what are the benefits and success stories!

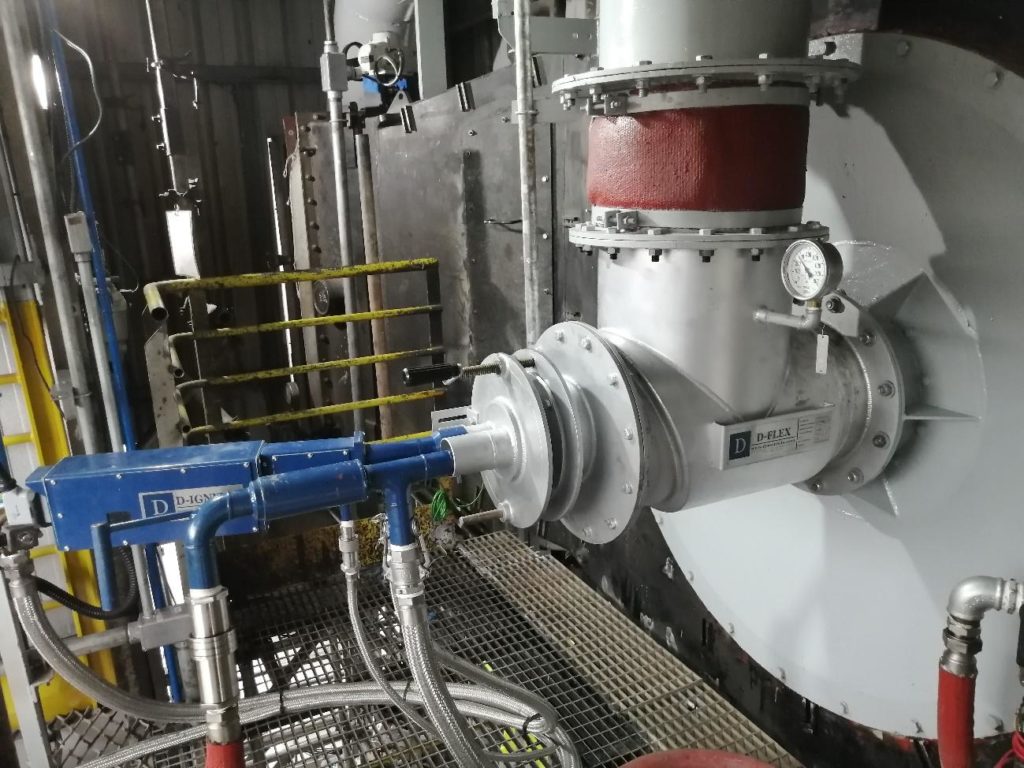

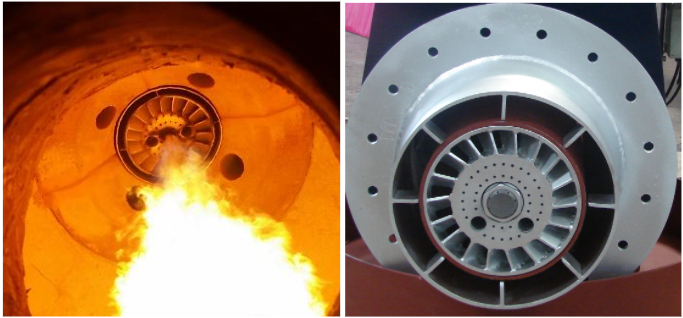

Early 2022, the new D-Flex burner for a Hot Gas Generator (HGG) was commissioned in one of the largest grinding systems in the world, the cement mill at LafargeHolcim’s industrial plant in Barroso (Minas Gerais – Brazil). Although the process already uses hot gases from the rotary kiln, the HGG proves to be necessary to fulfill and stabilize the energy power in addition, for supplying 100% of the gases in the event of a kiln outage, which is common during maintenances.

Reaching a little over 2 m in length (6.6 ft), the burner has a maximum power of 35.6 Gcal/h (141,2 BTU/h) and a nominal consumption of 3.750 kg/h (8.250 lb/h) of fuel oil, but the Dynamis project has a unique feature, operating with a very high turndown, as indicated at the table below with the project characteristics. This way, it becomes possible to operate in all the conditions described before, either at low load to fulfill the kiln hot gases, or in operation at 100% of its capacity.

| D-FLEX® BURNER | |

| PARAMETER | VALUE |

| Nominal Power | 35,6 Gcal/h (141,2 BTU/h)41,3 MW |

| Fuel | Diesel Oil Oil 1A |

| Turndown | 1:25 |

| Maximum Fuel Consumption | 3.750 kg/h (8250 lb/h) |

| Minimum Fuel Consumption | 150 kg/h (330 lb/h) |

| Fuel Oil Pressure | 7 bar (101,5 psi) |

| Compressed Air Pressure | 6 bar (87 psi) |

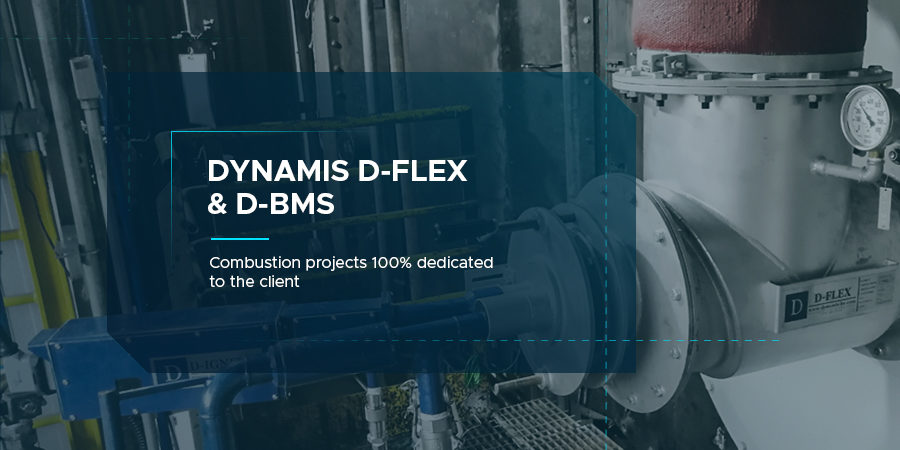

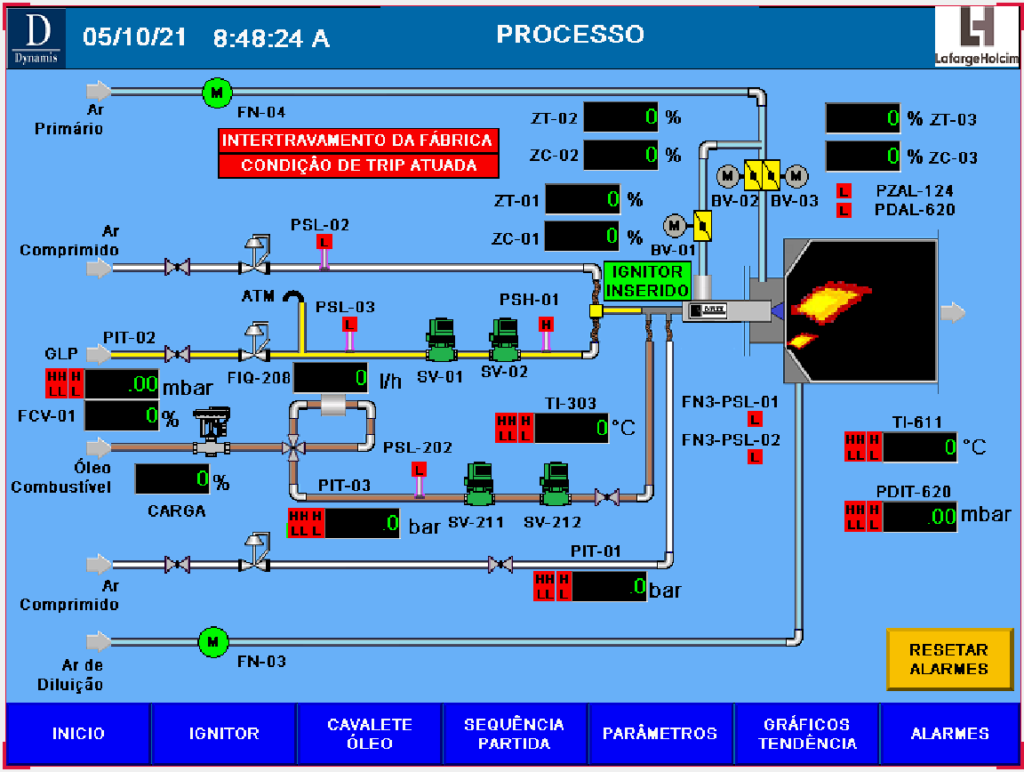

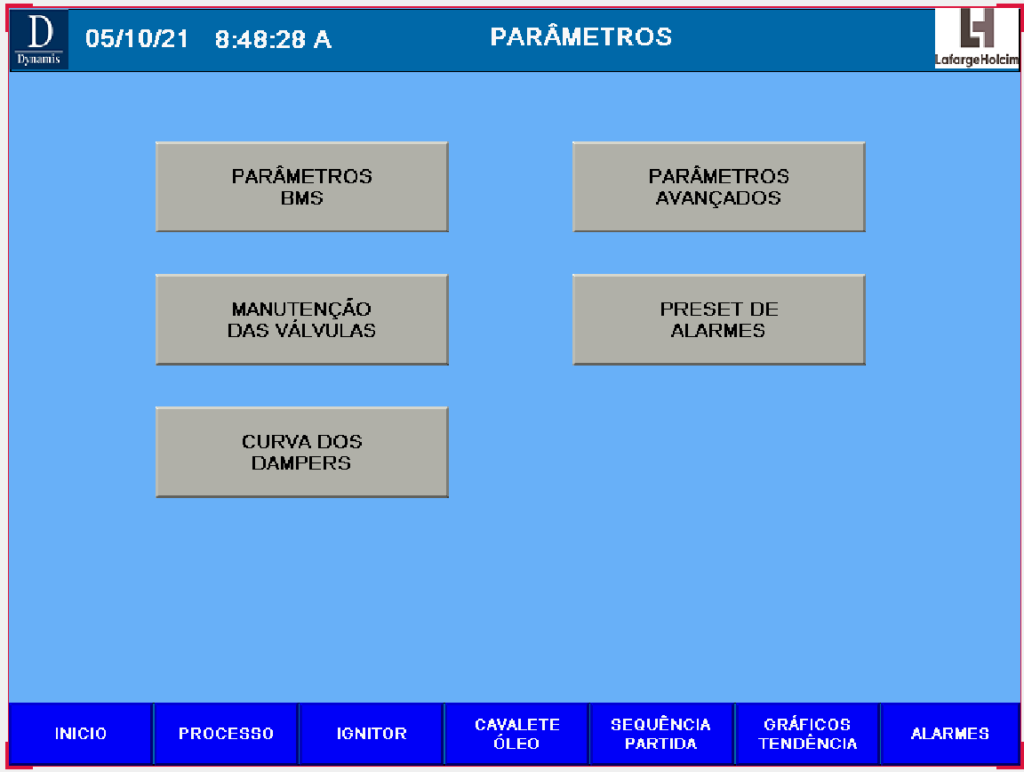

With our new technology, high burning efficiency and reliability were obtained with Dynamis’ burner and accessories also installed in the system: D-Igniter pilot burner, D-Lance oil lance, D-Rack valve rack for pilot burner and especially the safety system D-BMS – Burner Management System, which includes Safety PLC with touch screen HMI. This entire scope of supply can be seen in the figures below.

Another advantage in replacing the burner was the nationalization and reduction of costs and deadlines in the supply of spare parts, providing a more agile and reliable maintenance for the customer’s planning and programming. Also, LafargeHolcim acquired Dynamis’ engineering excellence standards and technical assistance with the best professionals in the thermal engineering, which enabled the project to be successfully implemented, despite the various challenges presented during the project and its operation.

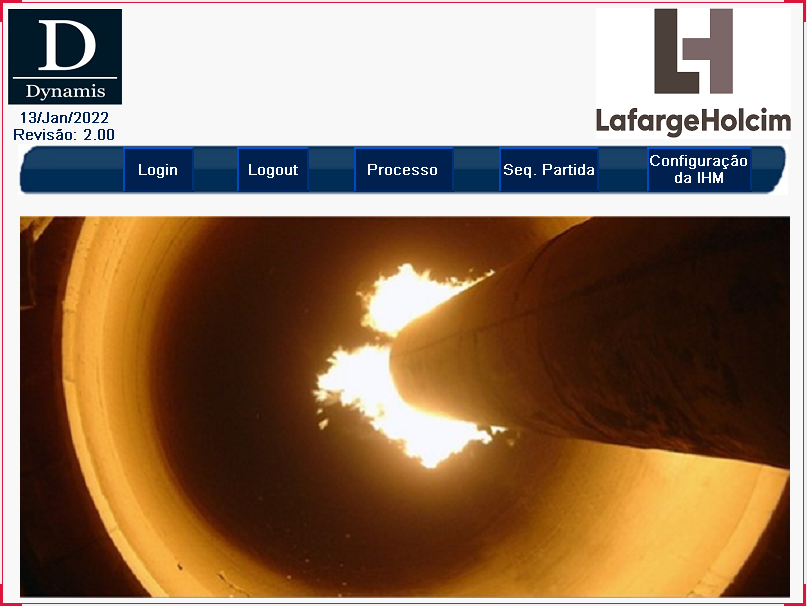

In addition to all the quality of the D-Flex burner provided by Dynamis, another highlight was the BMS Safety PLC. The system designed 100% focused on the specific application of LafargeHolcim (LH) in Barroso-MG, is a combustion management system (BMS – Burner Management System) designed to be used as automatic and safe control of the ignition of the burner in the combustion chamber of the cement mill. The ease of adjustment, the programming dedicated to the application and the possibility of continuous improvement of the system are among the advantages that Dynamis presents to LH in this project. This exclusive dedication can be seen on the screens of the BMS provided: starting screen, general and specific process monitoring screens and screen for system adjustment and HMI (Human Machine Interface) parameterization.

With the supply of the new DYNAMIS D-FLEX burner, Lafarge Holcim Barroso cement grinding unit received equipment and instruments focused on its application, developed to fit their specific demands, whether in instruments and electrical improvements, in maintenance or, even more important, in safety. Dynamis provided complete professional engineering support with technical assistance throughout the commissioning, startup and operation process, leaving the burner operating according to its design characteristics and meeting all of the technicians’ expectations. Once again, Dynamis delivers quality and reliable service to satisfied customers with our exclusive technology and its benefits.

LEARN MORE ABOUT DYNAMIS D-FLEX TECHNOLOGY

D-FLEX burners have flexibility as their main feature. With adaptive controls, intelligent design and simple setup, they have flexibility in fuels, application and flame profile. They can work with gaseous and liquid fuels and are suitable for various operations of the thermal industry. Among them, the operations in calciners, hot gas generators, rotary calcining furnaces, dryers and grinding.

The flame profile of the D-FLEX can be customized according to the customer’s needs. Long or short flame profile, wide or narrow, it can be controlled through the air channels flows, one of air with axial components and the other of air with rotating components. Control is remote and done directly from the operating room with the help of safety and management systems.

Additional Features:

In addition to flexibility, D-Flex also offers distinctive qualities for your application, as follows.

• BMS Burner Management System security system;

• Flame detector/sensor;

• Failure controls;

• Own instrumentation;

• Optimization of combustion efficiency using CFD simulations;

• Injection nozzles for liquid fuels with air nebulization;

• Adjustments made directly from the operating room;

• Low-Nox.

At Dynamis, we develop the best product for your process, always offering the best technology and our experience to achieve the best results, whether you need a simple burner replacement or a new one with a project focused on your application. To learn more, contact Dynamis and make your request for a D-FLEX tailored to your application.

Dynamis Team